Container Handling Systems

Our experienced team can meet your container handling system needs. From drawing on data to improve efficiencies to engineering right-fit solutions that maximize production, our full-service approach ensures that what matters most to you is our priority.

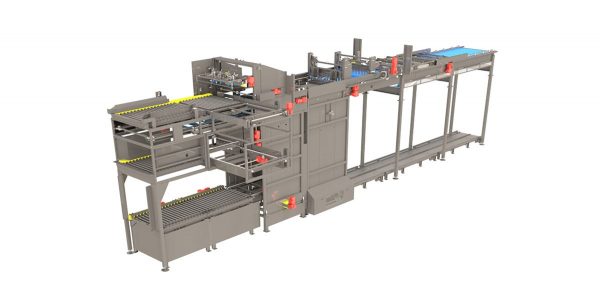

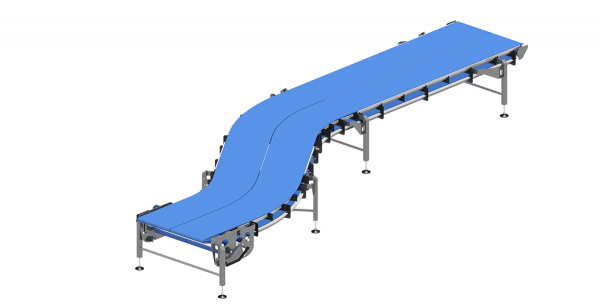

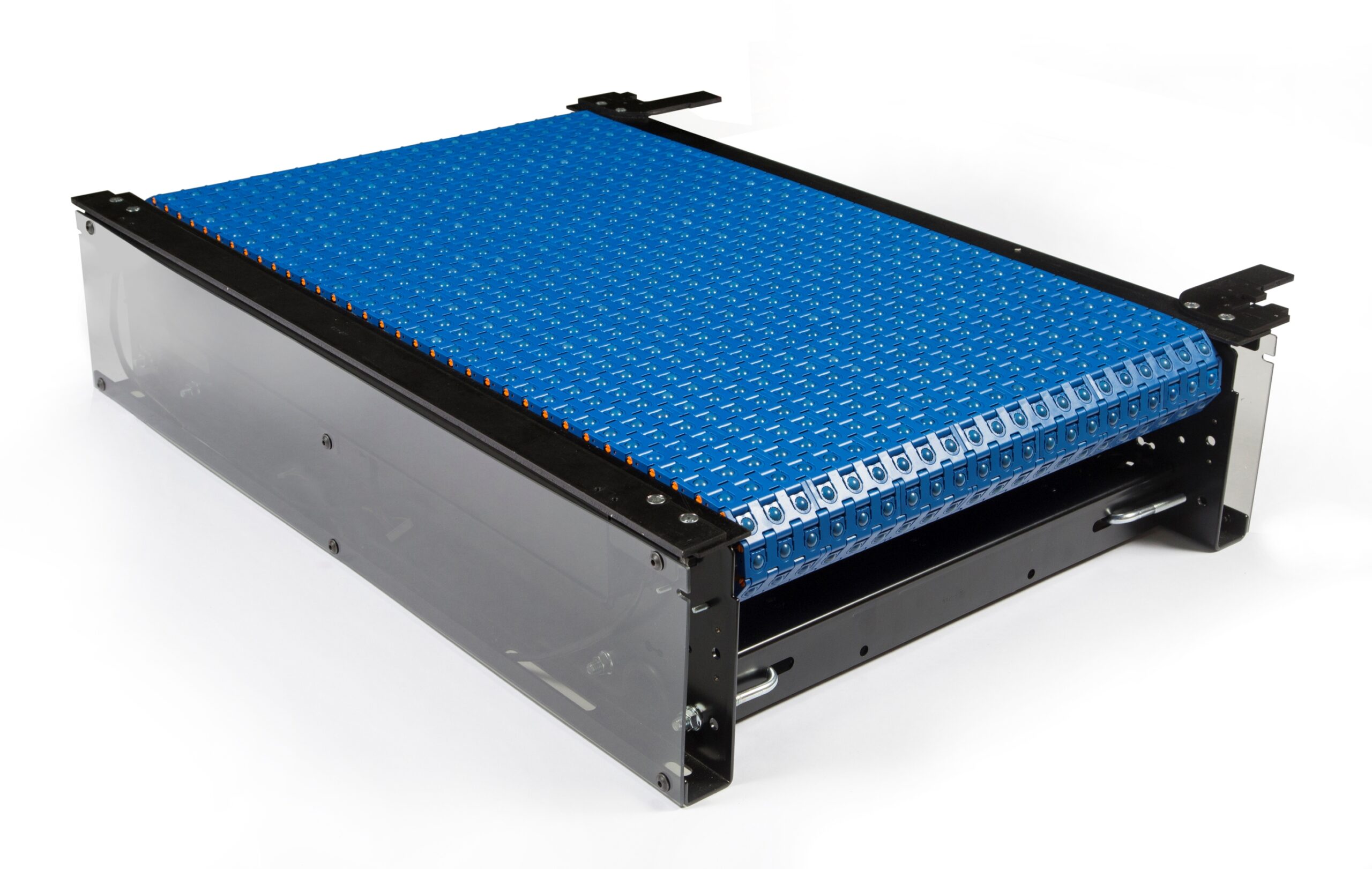

Conveyor Systems

Container Making, Container Filling, Case Handling Solutions

From standard design, quick ship conveyors to customizable engineered solutions utilizing custom mat top and table top designs, we have the solution to fit your needs. Choose from our container handling equipment including laners, single filers, gripper elevator/lowerators and many more, products will flow effortlessly to your customers.

View AllServices

Machine Upgrade Kits, Preventative Maintenance, Parts & Services

Years of experience and an ongoing passion to improve are at the heart of our Service teams. Using data to drive decisions and a deep understanding of your business enables container handling, end-to-end solutions to be developed that improve your return on investment and drive more business.

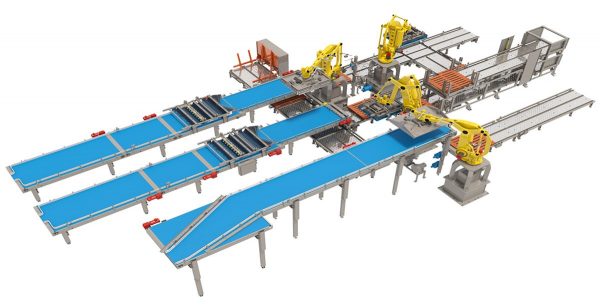

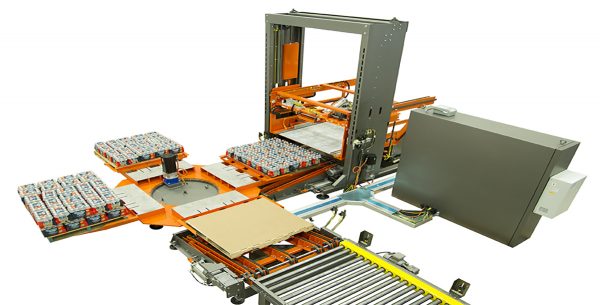

Palletizers & Depalletizers

High Level Bulk, Low Level Bulk, Case & Robotic

Whether it’s the start or end of the line, our palletizers and depalletizers provide the flexibility to adapt to changing load configuration demands, maximizing throughout. And, with the industry’s fastest depalletizer on the market and Busse brand name, products are in customers’ hands sooner than ever. We offer High Level Bulk, Low Level Bulk, Case and Robotic Palletizers and Depalletizers

View AllWhy Choose Us

With over 75 years in business, our team has the experience and expertise needed to deliver you the best material & container handling solutions. From replacing pieces of equipment to installing a new line, we’re committed to understanding your needs, both current and long-term. As a leading conveyor & equipment manufacturer, you can expect us to always deliver on time and on budget.

Years of Dedication & Experience

Percent on-time Shipments

Percent Committed to Innovation & Engineering Excellence

Get in Touch Today

We deliver dependable, end-to-end container handling

solutions to drive your efficiency and profitability.

Want to learn more? Fill out the form to

the right and we will contact you shortly.